Overview

Smart Factory Solutions on AWS: Accelerating Manufacturing 4.0

Improve Efficiency and Create Breakthrough Value in Manufacturing

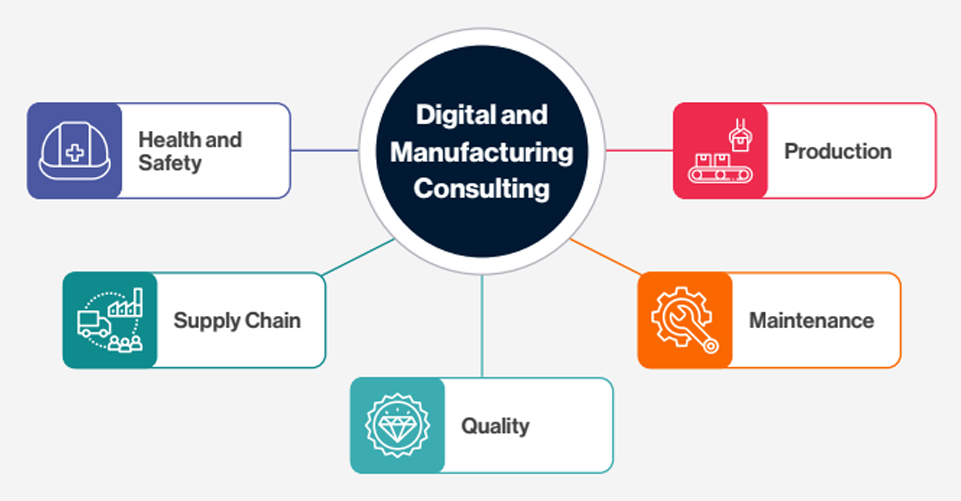

Accelerate your intelligent manufacturing journey with Hitachi Digital Services solutions for manufacturing. Hitachi Digital Services Industry Cloud accelerators and services on AWS for manufacturing includes specially designed OT DataOps- specific accelerators that help improve production, quality, maintenance, supply chain, and health and safety.

Digital Solutions and Services Focused on Business Outcomes

Hitachi’s Smart Factory suite of accelerators, frameworks and services connects the entire manufacturing value chain to deliver accelerated digital industrial transformation. Hitachi Digital services is ready to share our experience as a manufacturing company and solution provider with your team. Drive operational excellence to save cost, unlock new revenue opportunities and create new business models. It all starts by understanding your real business needs and then designing digital industrial solutions and new business models that consider your organizational, technical and business capabilities. We run a discovery session with you to establish an agile and business-driven proof of value. We consult with stakeholders and analyze data based on our vast experience in IT, operational technology (OT) and manufacturing to prioritize the important focus areas. Working with you and your teams, we arrive at the ideal outcome-based technology solutions to support your continued digital transformation.

Rely on Our Unmatched Industrial and Digital Capabilities

What sets Hitachi Digital Services apart is our consultative approach in combination with our software and deep OT and IT expertise, which is just one component of an end-to-end offering that spans operations evaluation, strategy and implementation. Our value engineering is specific to manufacturing and applies results from our own manufacturing businesses and proven intellectual property from our own products and solutions.

Hitachi’s Omika Works Recognized as an “Advanced 4th Industrial Revolution Lighthouse Factory”

Tokyo, January 10, 2020 — Hitachi, Ltd., announced that the Omika Works, which manufactures information control systems for social infrastructure systems and industries, was recognized by the World Economic Forum (WEF) as a Lighthouse advanced factory.

Turn Your Vision Into Value Faster

At Hitachi Digital Services, we bring together our learnings as a manufacturer with our domain expertise to enable outcomes that will accelerate your digital industrial transformation. We work with you to blend an approach that includes off-the-shelf solutions and specific, engineered solutions based on our solution cores, focusing on the production, quality, maintenance, supply chain, and health and safety domains.

Production

Our production solutions include tools for the real-time collection, processing and visualization of all relevant data on your shop floor, including machine learning (ML) tools for real-time process insights, end-to-end traceability, dynamic scheduling and much more.

Hitachi Digital Services production solutions enable process insights and optimization to maximize your throughput, boost your asset performance and efficiency, and help identify and eliminate shop-floor bottlenecks.

Maintenance

Leverage IoT and analytics for better equipment maintenance. Our maintenance solutions include equipment monitoring, KPI and trends analysis, anomaly detection, remaining useful life estimation, failure impact prediction, and predictive and prescriptive tools.

Balance the risk, cost, performance and reliability of your assets to maximize your predictable production at the lowest sustainable maintenance cost.

Quality

Transform process performance with an intelligent digital solution that gives you quality discrepancy detection, root-cause analysis and real-time notifications for production quality and traceability. Capabilities include descriptive qualitycontrol and predictive and prescriptive quality assurance.

Anticipate and manage your product quality issues to lower the costs of rework and reduce scrapped material, lost opportunity and lower line performance.

Supply Chain

Your manufacturing agility and supply chain responsiveness are key to meeting customer demand. You need greater visibility and predictability to optimize your supply chains and gain competitive advantage, stay agile, control costs and reduce working capital.

Real-time supply chain optimization uses data analysis to assess what-if scenarios to aid your tactical decision-making for actors across the supply chain, improving your customer service and inventory levels.

Health and Safety

Our digital health and safety solution for manufacturing combines strategic consulting with new digital technologies, such as 3D lidar, video, artificial intelligence (AI), radio-frequency identification (RFID) and data analytics, to reduce risk and optimize safety strategies, procedures and approaches.

Build an effective and holistic health and safety strategy for fewer injury claims, better employee retention, improved morale, reduced legal costs and brand protection.

Asset Insights

Asset performance is a key contributor to operational effectiveness, productivity and cost in manufacturing. Solutions for asset insights help you to balance the risk, cost, performance and reliability of your machinery, assets and infrastructure.

Enable critical work processes to safely maximize your predictable production at the lowest sustainable maintenance cost, while achieving quality targets within your business’s risk profile.

What Hitachi Technology Can Do for Manufacturers

Hitachi has created groundbreaking technology solutions for use in manufacturing, leveraging AI, ML and advanced data management. Smart Factory accelerators and services integrates data from all kinds of OT equipment, offering alerts and visualization for operators. Providing supply chain, safety, machine, production and quality analytics, Smart Factory accelerators and services drives transformational business outcomes, and can store, curate and transform data for analytics, model training and reporting. Hitachi also has advanced IT + OT data integration and management expertise, along with data and cloud application migration, management and enablement. Our unique combination of deep OT expertise, extensive IT capabilities and hands-on global experience as a manufacturer makes Hitachi the best guide for your digital transformation journey.

Business Benefits of Digital Solutions Across Your Manufacturing Enterprise

Today’s manufacturers are laying the foundation for success in a transformed world by bringing digital technologies to areas of focus across their business. Although the outcomes sought by production, quality, maintenance, supply chain, and health and safety stakeholders vary, every domain benefits from digital technology.

Production Manager

With digital production solutions based on real-time manufacturing data, production managers can deliver high-quality products consistently and on time with increased throughput, improved delivery, and little or no unplanned downtime or scrap.

Quality Manager

An intelligent digital solution gives quality control teams end-to-end traceability, real-time access to data that is critical to improve quality, faster root cause analysis, better first-pass yield and reduced cost of quality.

Operational Excellence Manager

Digital production solutions can automatically highlight factory bottlenecks and provide relevant 4M data to jump-start Kaizen events so operational excellence managers don’t have to collect data manually.

Manufacturing Process Manager

Manufacturing process engineers can understand the gap between designed and actual performance of new or existing equipment with digital production solutions, which provide historical data and ML-based insights to optimize processes.

Maintenance Manager

With digital maintenance solutions, maintenance managers can enhance equipment availability and life span, optimize spares and coordinate between maintenance and operations to improve recovery rates and minimize costs.

Supply Chain Manager

With a highly configurable solution, supply chain managers gain real-time insights to optimize and reduce risks across their partner value chain. This can drive improvements in resiliency, agility, responsiveness and costs.

Environment, Health and Safety Manager

Health and safety capabilities detect potential danger and alert employees via video and 3D lidar analytics solutions. With our digital solution, you can improve work processes to enhance quality, performance and safety.

We Understand Your Needs Because We are A Manufacturer, Too

Fuel data-driven transformation that propels supply chain productivity, uptime, quality and safety gains with solutions for manufacturing from Hitachi Digital Services. Apply powerful and outcome-driven use cases that align with your business value and accelerate your intelligent manufacturing improvements.

- Comprehensive solutions developed with deep manufacturing experience and process-improvement best practices stress tested in Japan.

- Vast consulting experience and IT and OT know-how.

- Accelerated time to value, flexibility and modularity.

- Long-term focus on our customers for sustained improvements.

We see companies adopting technology today without realizing its full potential. We recognize that it is really a people and process problem, so we have implemented a change management approach that takes training and incremental changes into account, allowing people to operationalize the solution and transform the organization.

We Are Hitachi Digital Services

We guide our customers from what’s now to what’s next by solving their digital challenges. Working alongside each customer, we apply our unmatched industrial and digital capabilities to their data and applications to benefit both business and society.

Let us help you on your digital Transformation journey. We understand the bits and bytes as well as what it takes to get the job done in manufacturing. Visit hitachids.com for more information.